Thomas-Morse Scout

Limited Edition

Thomas-Morse S4C Scout

Case made from:

Le Rhone 9C steel pistons

41 mm case

$10,500.00

| Movement | Swiss automatic, 42-hour power reserve |

|---|---|

| Case Size | Ø 41.00 mm |

| Water Resistance | 200m |

| Strap Material | Stitched, hand-cut Horween leather |

Sopwith Watch Company

Thomas-Morse Scout

Limited Edition

The ultra-rare Thomas-Morse Scout is the world’s first timepiece to feature an in-house forged case made entirely from the pistons and valve guides of a Le Rhône 9c rotary engine manufactured in 1918 to power the United States Air Service’s famous pursuit trainer.

Travelers can use the Aero Marquis’ GMT function to monitor a second time zone, marked by an angled bronze 24 hour chapter ring reminiscent of the casings of early 20th century aviation instruments. With magnetic resistance to 20,000 Gauss, water resistance to 200 meters and a functional azimuth bezel, the Aero Marquis is the perfect multi-sport adventure watch. Swiss X1 grade C3 GL & X1 grade Light Old Radium GL keep the Thomas-Morse Scout Limited Edition legible day and night.

The twin dots at noon validate this piece as an authentic Sopwith watch with a case that is guaranteed forever.

The shock resistant caliber 2893-A2 Élaboré movement offers high grade accuracy and legendary Swiss reliability. The Thomas-Morse Scout edition sports an Emerald Green sunburst dial with Mariner Blue hands with the American tri-bar at 6 o’clock.

Read

The SPECS

Case

Materials

Thomas-Morse S4C Scout Le Rhone 9C steel pistons

Caseback, 316L stainless steel, signed, engraved

Dimension

Ø 41.00 mm

Water Resistance

Water-resistant to 200 meters

Lug distance

21mm

Lug-to-lug

49 mm

Hardness

Titanium carbide coating 1500 HV

Enhanced historic steel 168.2 HV

manufacturing

Steel processed, melted, poured, cast, laboratory analysis, enhanced to 5360 grade steel at Sopwith Foundry, Houston USA

Finish

Bead blasted finish

Titanium carbide physical vapor deposition coating

Magnetic field resistance

20,000 Gauss

Dial & Hands

Dial

3 piece

Double stainless steel stacked

Oblique 25-degree bronze 24 hour chapter ring

Hands

Diamond cut steel

Bezel

Bronze

120-position

Unidirectional rotating

Azimuth +/-3 degrees

Luminous sapphire insert

Movement & Functions

Movement Type

Automatic, bidirectional rotor

Mecaline Specialities Calibre 2893-A2 Élaboré,

ETA SA Manufacture Horlogère Suisse,

Grenchen, Switzerland

Power reserve, 42 hours

Frequency, 28,800 bph

21 jewels

Functions

Hours, minutes, seconds, GMT, azimuth

LUME

Swiss multi-layered, Swiss X1 grade Light Old Radium GL

Anti-shock system

Jeweled Incabloc SA Novodiac, Durnico steel/brass

La Chaux-de-Fonds, Switzerland

CROWN

Signed, extruded diamond grip bronze, 3.50 x 7.00 mm

Strap

Material

Stitched, hand-cut Horween leather

Color

Brown

Buckle

Tang buckle with Sopwith Logo emboss

Sopwith Aero Marquis

Thomas-Morse Scout Limited Edition

Written for the Sopwith Watch Company by World War I aviation historian Stephen Skinner, author of “THE STAND: The Final Flight of Lt. Frank Luke, Jr.,” and 2007 recipient of the Arizona Veteran Association’s Luke Award.

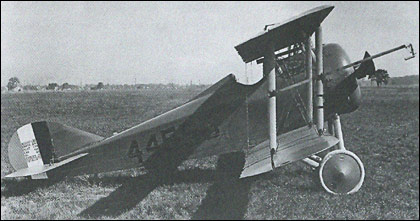

The Thomas-Morse Scout S-4C was the most successful fighter training aircraft of the United States Air Service in the First World War. Affectionately known as the “Tommy,” the S-4C was the final airplane flown by many American cadets before sailing to France for combat duty on the Western Front.

The primary engine for the Thomas-Morse Scout, the Le Rhône 9C rotary, was truly a marvel of its day. Introduced in Paris in 1912, the 268 pound engine produced 80 horsepower at 1,200 RPM with a 4.5:1 compression ratio. The Le Rhône 9C set multiple pre-war long distance flight records across Europe. It then powered Georges Legagneux’s Nieuport to a new world altitude record in 1913, achieving a height of over 20,000 feet. Even before the outbreak of hostilities in 1914, the Le Rhône had already secured a rich and enduring legacy as a superb aeronautic powerplant.

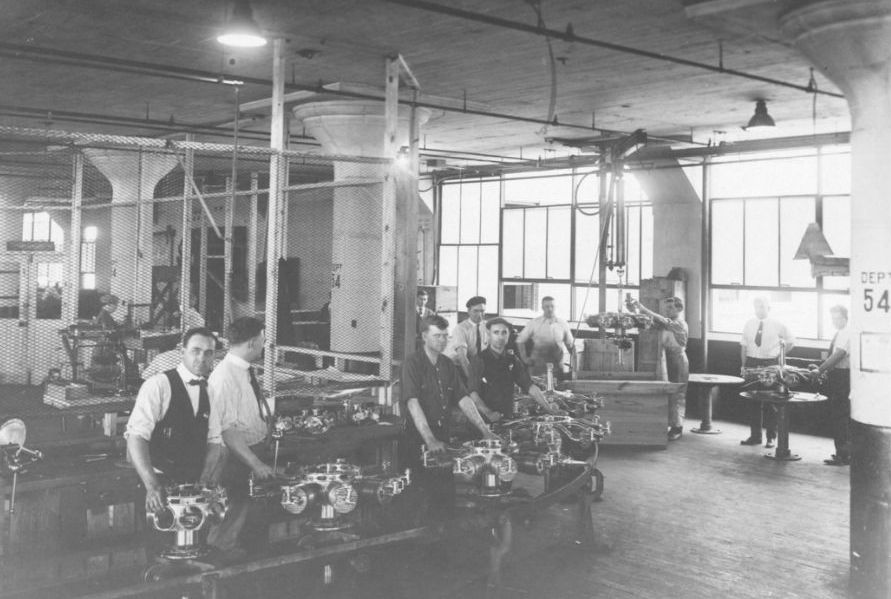

The Thomas-Morse Aircraft Corporation of Ithaca, New York was owned by Westinghouse. The company secured a contract to provide 465 training aircraft to the US Army in 1917. The Union Switch & Signal company of Swissvale, Pennsylvania (also owned by Westinghouse) produced the S-4C’s Le Rhône 9C rotary engine under license from its French designers. This arrangement kept production of both the American-made Le Rhône 9C and the Thomas-Morse Scout under the umbrella of a single American corporation, eliminating the possibility that domestic airplane assembly might be delayed while waiting for Le Rhône engines to be shipped from France.

A sample engine and drawings were delivered to Swissvale from Paris in September 1917, followed by the arrival of French design engineer M. Georges Guillot, who sailed to America to oversee production and assembly. Union Switch & Signal speedily built two new factories and promised their employees a ten percent bonus to kickstart the project. The company was to be paid $3,250 per engine and had no intention of running behind on fulfillment and delivery.

In European hands the 9C had already powered several famous fighter airplanes for various Allied nations on the Western Front. The Nieuport 11 was the first in a series of enormously successful French fighter airplanes that were also flown by British, Belgian and Italian forces. Also powered by the Le Rhône 9C was the Royal Flying Corps’ Sopwith Pup, the light and highly maneuverable predecessor to the legendary Sopwith Camel.

The British and French routinely used underpowered two-seat aircraft or obsolete front-line fighters to train their pilots, but America wasn’t stocked with flying fields full of old airplanes. The United States Air Service had a pressing need for an aircraft that could bridge the gap between basic two-seat trainers like the Curtiss JN-4 and the more sophisticated, high-performance fighter aircraft used on the Western Front. The S-4 Scout was designed by British aviation engineer Benjamin Thomas to fill this role.

As a former employee of the Sopwith Aviation Company, Thomas’ influence produced a light, agile advanced training airplane that strongly resembled the Sopwith fighters already in the field. With its torquey engine and extremely heavy tail section, the Tommy didn’t fly like a dream. But it did fly very much like the rotary powered fighters in front line service in France. And that was the whole point.

US Army test pilot Henry Garrett Smith flew both the B and C model of the Thomas-Morse Scout at the Aviation Depot in Montgomery, Alabama throughout 1918. After his first flight in the Tommy, Smith recalled,

They pulled the chocks and I went rocketing down the side of the field with the engine blipping and blooping, wandering right and left, for the rudder was useless on the ground and you turned her with the ailerons… (it) was so tail heavy that after half an hour your arm would get so damn tired from pushing the stick away from you that you would brace your elbow against your gut for relief… (but) after I got to know them, we had some swell times.

At Union Switch & Signal in Swissvale, production of the amazing Le Rhône 9C engine was in full swing by spring 1918. The company would eventually turn out enough Le Rhônes to power the Air Service’s entire fleet of Thomas-Morse Scouts. Georges Guillot, the French engineer overseeing American production, was estatic about the final result, saying, “These are the best constructed rotary engines which have ever been built.”

Back in New York, the Thomas-Morse factory in Ithaca was building thirty Scouts per week by mid-1918. At war’s end, Tommies were in use at almost every military flying field in America. Some six hundred Thomas-Morse Scouts were delivered before the US government finally canceled the contract in December, with another two hundred airplanes assembled later from spare parts.

The Thomas-Morse Scout trained America’s first generation of fighter aces and went down in history as the first-ever single seat airplane designed specifically as a trainer. When the Scout was phased out of military training service shortly after the Armistice, the Army’s stock of Le Rhône 9C engines was collected and sold to the public at the surplus rate of fifty dollars each.

Many of these legendary rotaries found their way into civilian aircraft between the world wars. Some were used for barnstorming, stunt shows, or to offer joy rides to paying customers in rural areas. Many more were retrofitted into airplanes originally designed for other engines, but the availability and reliability of the Le Rhône made it an easy choice for civilian aviators in the 1920s.

Surplus Tommies and their Le Rhône engines even found their way into Hollywood where they were used in cinematic films set in World War I including Howard Hughes’ Hell’s Angels (Ben Lyon, Jean Harlow, 1929) and Dawn Patrol (Richard Barthelmess, Douglas Fairbanks Jr., 1930).

The case of the Sopwith Aero Marquis Thomas-Morse Scout Limited Edition GMT is crafted from one of these wartime production engines. Specifically, the entire case is made from the cylinder, piston and connecting rod of a Le Rhône 9C rotary engine manufactured under license by the Union Switch & Signal Company in Swissvale in early to mid-1918 for use in the Thomas-Morse Scout.

Sopwith Watch Company supports the restoration of historic aircraft. The parts rescued in the making of this product were unfit for use and beyond repair. The salvageable parts of this Le Rhône engine, including the full engine block, are now undergoing complete restoration at Murrin Antique Aero in Pennsylvania.

Watch Case Warranty – Forever

Sopwith watch cases are guaranteed forever against manufacturing and workmanship defects, cracking, breaking, lug failure or structural damage to the steel as determined by Sopwith Watch Company. Case warranty does not include cosmetic damage and scratching from normal use.To submit a claim, send the complete watch to Sopwith Watch Company with a brief description of the damage. If a replacement is issued, it will be provided free of charge including re-assembly of the watch.

Due to the scarcity of historic steel, Sopwith may at its discretion substitute the case with one made from the steel of a different airplane/automobile/vehicle or replace the watch case with another model.

All Other Parts – 1 Year

Sopwith‘s 1-year warranty covers manufacturing defects excluding damage resulting from normal wear and tear, misuses or accidental impact (including but not limited to scratching or wearing of PVD coatings, scratches, chipping of crystal), unauthorized repair, opening watch case back, adjustment to movement or any other modification work done outside our authorized service center, damage done to bracelets, straps or accessories, water infiltration or damage in watch due to failure to secure screw-down crown or exposure of watch to depths exceeding rated water-resistance.

Aero Marquis Watch Case Manufacturing

Sopwith is proud to manufacture the finest – and rarest – watch cases in the world, guaranteed forever. Our proprietary steel enhancement process creates a watch housing that meets or exceeds industry standards while preserving the original historic metals. Steel manufactured under wartime conditions in the early 20th century was of poor quality, prone to rust, relatively soft and unsuitable for continuous contact with human skin. It was built to endure a few months of combat service before being destroyed or scrapped. Once historic steel is rescued from destruction by Sopwith Watch Company, our staff metallurgists disassemble, wash and silicon blast each piece at the Sopwith Foundry. The individual components are then laboratory tested to determine their composition via a time-consuming and labor intensive process. The cylinders of a 1918 Gnome aviation engine – for instance – contain seven distinct types of steel, each of which must be individually analyzed. The laboratory analysis of every piece is then compared to the composition of Aerospace Material Specification 5360 grade stainless steel. Each lot of historic steel is melted in-house at the Sopwith Foundry in Houston by Sopwith staff members. The steel is then enhanced with the necessary elements to raise the final metal to AMS 5360 grade, or – in the case of very old steel – as precisely as possible to AMS 5360.In order to achieve AMS 5360 status, Sopwith must adhere to standards established by the Society of Automotive Engineers to create a steel that is suitable for use in specialized applications. These standards place exact limits on the elemental composition of the steel, minimum tensile and yield strengths, and solution heat-treated finishing. Anti-magnetic and upgraded to AMS 5360 standards, the historic steel is cast into watch housings at the Sopwith Foundry. Each case is then polished and coated with a protective film of titanium carbide. The physical vapor deposition method was chosen for it’s lower application temperatures which preserve the precise elemental content of the steel. The Sopwith Aero Marquis watch case is made of authentic historic steel, yet meets or exceeds industry standards for corrosion resistance, strength and durability. All Sopwith watch cases are guaranteed forever.

Related products

-

Limited to 55 watches.

Focke-Wulf Fw 190

Baltic Winter$4,900.00 View cartFocke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case -

Limited to 59 watches.

Messerschmitt Bf 109

Pas-de-Calais$4,600.00 View cartMessershmitt Bf 109

Case made from:

Cockpit armor plating

41 mm case -

Limited to 53 watches.

Focke-Wulf Fw 190

Tunisian Desert$5,700.00 View cartFocke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case