Focke-Wulf Fw 190

Tunisian Desert

Focke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case

$5,700.00

| Movement | Swiss automatic, 42-hour power reserve |

|---|---|

| Case Size | Ø 41.00 mm |

| Water Resistance | 200 meters |

| Strap Material | Stitched, hand-cut Horween leather |

Sopwith Watch Company

Focke-Wulf Fw 190 Series

Tunisian Desert

With an in-house case crafted from an original World War II Focke-Wulf Fw 190 fighter plane, this limited edition of Sopwith’s Aero Marquis is the ultimate traveler’s companion.

The Aero Marquis’ GMT function tracks two time zones, offset by a bronze screw-down crown and angled 24 hour chapter ring. With magnetic resistance to 20,000 Gauss, water resistance to 200 meters and a functional azimuth bezel, the Aero Marquis is the perfect multi-sport adventure watch. The shock resistant caliber 2893-A2 Élaboré movement offers high grade accuracy and legendary Swiss reliability.

The case was forged at the Sopwith Foundry in Houston from the unsalvageable cockpit armor plating of the Luftwaffe’s feared Focke-Wulf Fw 190 fighter – specifically, the rounded armor encasing the seat and protecting the pilot’s lower back from rear attack.

The stitched, vintage strap is genuine Horween leather and the hands resemble the shape of the altimeter needle on an original Focke-Wulf fighter. The twin dots at noon validate this piece as an authentic Sopwith watch with a case that is guaranteed forever.

The desert sands of the Sahara meet the fertile Mediterranean coastline in northeastern Tunisia, producing a spectacular green, tan and charcoal landscape unseen anywhere else in the world. The Luftwaffe’s North African campaign saw the establishment of numerous airfields in this region, many of which were home to Germany’s premier fighter plane, the Focke-Wulf Fw 190. The Tunisian Desert Limited Edition Aero Marquis comes in Hemlock Green with a Zeus Charcoal sapphire bezel as a tribute to the airplanes that fought in the skies over Tunisia.

Read

The SPECS

Case

Materials

Focke-Wulf Fw 190 hardened steel cockpit armor plating Caseback, 316L stainless steel, signed, engraved

Dimension

Ø 41.00 mm

Water Resistance

Water-resistant to 200 meters

Lug distance

21mm

Lug-to-lug

49 mm

Hardness

Titanium carbide coating 1500 HV

Enhanced historic steel 168.2 HV

manufacturing

Steel processed, melted, poured, cast, laboratory analysis, enhanced to 5360 grade steel at Sopwith Foundry, Houston USA

Finish

Bead blasted finish

Titanium carbide physical vapor deposition coating

Magnetic field resistance

20,000 Gauss

Dial & Hands

Dial

3 piece

Double stainless steel stacked

Oblique 25-degree bronze 24 hour chapter ring

Hands

Diamond cut steel

Bezel

Bronze

120-position

Unidirectional rotating

Azimuth +/-3 degrees

Luminous sapphire insert

Movement & Functions

Movement Type

Automatic, bidirectional rotor

Mecaline Specialities Calibre 2893-A2 Élaboré,

ETA SA Manufacture Horlogère Suisse,

Grenchen, Switzerland

Power reserve, 42 hours

Frequency, 28,800 bph

21 jewels

Functions

Hours, minutes, seconds, GMT, azimuth

LUME

Swiss multi-layered, Swiss X1 grade Light Old Radium GL

Anti-shock system

Jeweled Incabloc SA Novodiac, Durnico steel/brass

La Chaux-de-Fonds, Switzerland

CROWN

Signed, extruded diamond grip bronze, 3.50 x 7.00 mm

Strap

Material

Stitched, hand-cut Horween leather

Color

Brown

Buckle

Tang buckle with Sopwith Logo emboss

Sopwith Aero Marquis

Focke-Wulf Fw 190 Series

Tunisian Desert Limited Edition

Written for Sopwith Watch Company by Barrett Tillman, award-winning author of “The Dauntless Dive-Bomber of World War II,” “When the Shooting Stopped: August 1945,” and more than 40 other books on World War II and the VietNam conflict

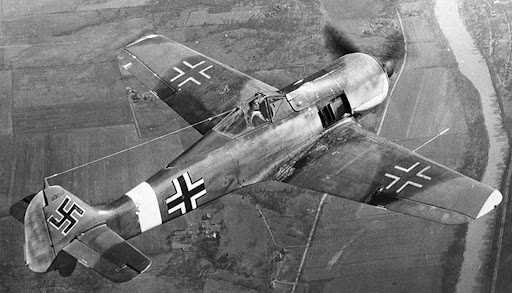

Renowned British Navy test pilot Captain Eric Brown rated the Focke-Wulf 190 as a world-class fighter, featuring “elegant lethality” with an unexcelled roll rate. He found little to choose between the FW-190 and the Spitfire Mk IX.

Brown knew Focke-Wulf’s guiding light, Dr. Kurt Tank – a polymath military, engineering and aviation talent. Following service as a World War I cavalryman, he learned to fly, worked for various firms, and settled at Focke-Wulf in 1931 as an engineer and test pilot. In 1938 the company chose him to design a contender for the Luftwaffe’s new fighter contract, and a happier melding seldom occurs.

First flown in 1939, the nascent FW-190 proceeded through engine teething problems before selecting the powerful, reliable BMW 801, a twin-row, 14-cylinder radial. When the FW 190A model debuted on the Channel Front in the summer of 1941, it immediately dominated the RAF’s Spitfire Mk V.

Lacking current intelligence, the British assumed that the radial-engine threat must be “some old Curtiss aeroplanes the Germans are using.” RAF legend Douglas Bader quipped, “If that was the case, we asked could we get some of those old Curtiss aeroplanes, please?” Actually, the Luftwaffe seldom flew captured French fighters such as the Curtiss Hawk 75 based on the P-36.

Lacking current intelligence, the British assumed that the radial-engine threat must be “some old Curtiss aeroplanes the Germans are using.” RAF legend Douglas Bader quipped, “If that was the case, we asked could we get some of those old Curtiss aeroplanes, please?” Actually, the Luftwaffe seldom flew captured French fighters such as the Curtiss Hawk 75 based on the P-36.

The Anglo-American landings in Morocco in November 1942 spurred the 190’s appearance in-theater, as Operation Torch opened the Wehrmacht’s western flank to strategic peril. The Allies pushed eastward into Tunisia where they encountered the 190 in a situation of Allied air superiority.

Flying over the open desert posed navigation problems similar to the sea. Long stretches with few landmarks could challenge everyone, including Focke-Wulf 190 pilots who sometimes flew long-range attack missions.

Flying weather in North Africa varied considerably. Though most days provided bright sunshine, the sandy expanse could produce massive dust storms – haboobs in Arabic – that obscured the sun.

Tactical aviation pilots and aircrews learned the advantages and disadvantages of operating in the theater. Generally the climate was pleasant with winter temperatures between the mid 40s to mid 60s Fahrenheit. Often with unlimited visibility, brilliant sunshine could gleam off canopy glass that became visible for miles, and when a plane’s camouflage paint blended with the terrain, there was no concealing a shadow flitting across the dunes.

The Focke-Wulf 190 Wurger (Shrike) was a rare “Butcher Bird” in British parlance, with a brief appearance in African skies. Apparently only two Luftwaffe groups flew the type in North Africa between November 1942 and May 1943 when the Axis Afrika Korps collapsed. The Gruppen detached from their parent commands were II/JG 2 and III/ZG 2 (originally a Bf 110 Zerstorer unit), redesignated III/SJG 10 in December.

The leading light of JG 2’s African deployment was Leutnant (soon Hauptmann, or Captain) Erich Rudorffer. A profligate claimer, he arrived with nearly 50 credited victories, and on January 8, 1943 he returned boasting of six P-40s and two P-38s in a half-hour combat. Five weeks later he repeated the claim with five P-38s and three Spitfires kills in an hour. When the Gruppe withdrew to France in early March, Rudorffer was credited with 26 victories in Africa. He ended the war flying Me 262s with some 220 Abschusse (kills).

Most 190s in North Africa were A models fitted with “tropical” air filters to operate in the region’s dust and sand. The few F and G ground-attack variants also received the “Trop” modifications. The close support variants were capable of carrying 250- and 500-kilogram (550 to 1,100 pound) bombs. And acknowledging the low-altitude AA threat, Schlachtflugzeug aircraft received additional armor plate.

A few other units took the 190 to Tunisia, flying reconnaissance missions as well as attack sorties.

The most heavily used bases were north and south of Tunis near the gulf, at la Fauconnerie and Sidi Ahmed, Kaiouan, Protville and El Aounia.

It was here that Royal Air Force pilot Benny Benham quickly learned of the Fw 190’s prowess in a dogfight along the North Africa coastline on January 2, 1943:

I followed down a [sic] Fw 190 which was diving at very high speed… I intended to cut across above him and nail him as he climbed up in front of me after pulling out of his dive. As I closed on him, he was obviously leaning back and watching me through the top of his cockpit hood, for as I was about to open fire, the fighter suddenly skidded violently to one side. It then skidded the other way and pulled over my head, ending up on my tail.

The Focke-Wulfe pilot turned the tables on his opponent and opened fire. Benham’s Supermarine Spitfire was riddled and he was lucky to escape with his life.

In Tunisia the Luftwaffe faced Royal Air Force and U.S. Army Air Forces opponents often flying the same aircraft, notably the Supermarine Spitfire and Curtiss P-40 Kittyhawk. The Allies’ three fighter weapons were British .303 and U.S. .50 caliber machine guns plus limited use of 20mm cannon.

Focke-Wulf pilots sat behind a 50mm (1.9 inch) armored glass windscreen, sloped at 50 degrees to reduce penetration much as tank armor often did. The seat was protected by 8mm (0.31 inch) armor on the back with a 13mm head and shoulder pattern plus 8mm plates above and below the seat pack and on the sides.

American fighters did not clash with 190s until early December, and seldom thereafter. In the following five months U.S. squadrons only claimed 40 Wurgers before the Tunisian campaign ended.

Over North Africa the Spitfire was the Wurger’s worst enemy among American fighter pilots. The 31st led the other six fighter groups with fifteen FWs credited as destroyed. Therefore overall, with the 52nd Group, Spitfires accounted for twenty-two of the U.S. total, followed by twelve for P-38 units and six flying P-40s.

The lone American ace against 190s in Tunisia was First Lieutenant J.D. Collinsworth, a 31st Fighter Group Spitfire pilot.

Collinsworth’s first 190 encounter provided an invaluable lesson. Spotting a Focke-Wulf below, he maneuvered to attack from behind, then remembered a briefing: “Where there’s one German, there’s two.” The young Texan turned in his cramped cockpit and saw the wingman closing in. He evaded with the lesson firmly in mind and shot down a Focke-Wulf a month for six months.

Six other USAAF pilots were credited with two FWs apiece in North Africa.

In the period that 190s were active in North Africa, Luftwaffe aircraft wastage was severe. Overall, the German air force lost more than 2,200 planes with attrition often exceeding two hundred percent per month. Fighters were particularly hard hit, reaching two-thirds of authorized strength. Nevertheless, the FW 190 exerted an influence on Allied pilots beyond its scale of issue.

The Sopwith Focke-Wulf Fw 190 Tunisian Desert Limited Edition timepiece, produced from the armor of an original Focke-Wulf Fw 190, recalls that rare legacy.

Watch Case Warranty – Forever

Sopwith watch cases are guaranteed forever against manufacturing and workmanship defects, cracking, breaking, lug failure or structural damage to the steel as determined by Sopwith Watch Company. Case warranty does not include cosmetic damage and scratching from normal use.To submit a claim, send the complete watch to Sopwith Watch Company with a brief description of the damage. If a replacement is issued, it will be provided free of charge including re-assembly of the watch.

Due to the scarcity of historic steel, Sopwith may at its discretion substitute the case with one made from the steel of a different airplane/automobile/vehicle or replace the watch case with another model.

All Other Parts – 1 Year

Sopwith‘s 1-year warranty covers manufacturing defects excluding damage resulting from normal wear and tear, misuses or accidental impact (including but not limited to scratching or wearing of PVD coatings, scratches, chipping of crystal), unauthorized repair, opening watch case back, adjustment to movement or any other modification work done outside our authorized service center, damage done to bracelets, straps or accessories, water infiltration or damage in watch due to failure to secure screw-down crown or exposure of watch to depths exceeding rated water-resistance.

Aero Marquis Watch Case Manufacturing

Sopwith is proud to manufacture the finest – and rarest – watch cases in the world, guaranteed forever. Our proprietary steel enhancement process creates a watch housing that meets or exceeds industry standards while preserving the original historic metals.Steel manufactured under wartime conditions in the early 20th century was of poor quality, prone to rust, relatively soft and unsuitable for continuous contact with human skin. It was built to endure a few months of combat service before being destroyed or scrapped.

Once historic steel is rescued from destruction by Sopwith Watch Company, our staff metallurgists disassemble, wash and silicon blast each piece at the Sopwith Foundry. The individual components are then laboratory tested to determine their composition via a time-consuming and labor intensive process. The cylinders of a 1918 Gnome aviation engine – for instance – contain seven distinct types of steel, each of which must be individually analyzed. The laboratory analysis of every piece is then compared to the composition of Aerospace Material Specification 5360 grade stainless steel.

Each lot of historic steel is melted in-house at the Sopwith Foundry in Houston by Sopwith staff members. The steel is then enhanced with the necessary elements to raise the final metal to AMS 5360 grade, or – in the case of very old steel – as precisely as possible to AMS 5360.

In order to achieve AMS 5360 status, Sopwith must adhere to standards established by the Society of Automotive Engineers to create a steel that is suitable for use in specialized applications. These standards place exact limits on the elemental composition of the steel, minimum tensile and yield strengths, and solution heat-treated finishing.

Anti-magnetic and upgraded to AMS 5360 standards, the historic steel is cast into watch housings at the Sopwith Foundry. Each case is then polished and coated with a protective film of titanium carbide. The physical vapor deposition method was chosen for it’s lower application temperatures which preserve the precise elemental content of the steel.

The Sopwith Aero Marquis watch case is made of authentic historic steel, yet meets or exceeds industry standards for corrosion resistance, strength and durability. All Sopwith watch cases are guaranteed forever.

Related products

-

Limited to 30 watches.

Thomas-Morse Scout

Limited Edition$10,500.00 View cartThomas-Morse S4C Scout

Case made from:

Le Rhone 9C steel pistons

41 mm case -

Limited to 55 watches.

Focke-Wulf Fw 190

Arctic Sea$4,900.00 View cartFocke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case -

Limited to 55 watches.

Focke-Wulf Fw 190

Baltic Winter$4,900.00 View cartFocke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case