Focke-Wulf Fw 190

Baltic Winter

Focke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case

$4,900.00

| Movement | Swiss automatic, 42-hour power reserve |

|---|---|

| Case Size | Ø 41.00 mm |

| Water Resistance | 200 meters |

| Strap Material | Stitched, hand-cut Horween leather |

Sopwith Watch Company

Focke-Wulf Fw 190 Series

Baltic Winter

Germany’s ill-fated decision to invade Russia in 1941 was based on a three-pronged attack plan code named “Operation Barbarossa.” The Wehrmacht’s upper invasion force – known as Army Group North – would march along the Baltic coastlines of Latvia and Estonia and then into Russian territory.

It was here, on the scenic coastal corridor south of Leningrad, that the German advance ground to a halt in August 1941. When the first Focke-Wulf Fw 190’s appeared late the following year, they were already fighting a losing battle in sub-freezing conditions against a numerically superior foe.

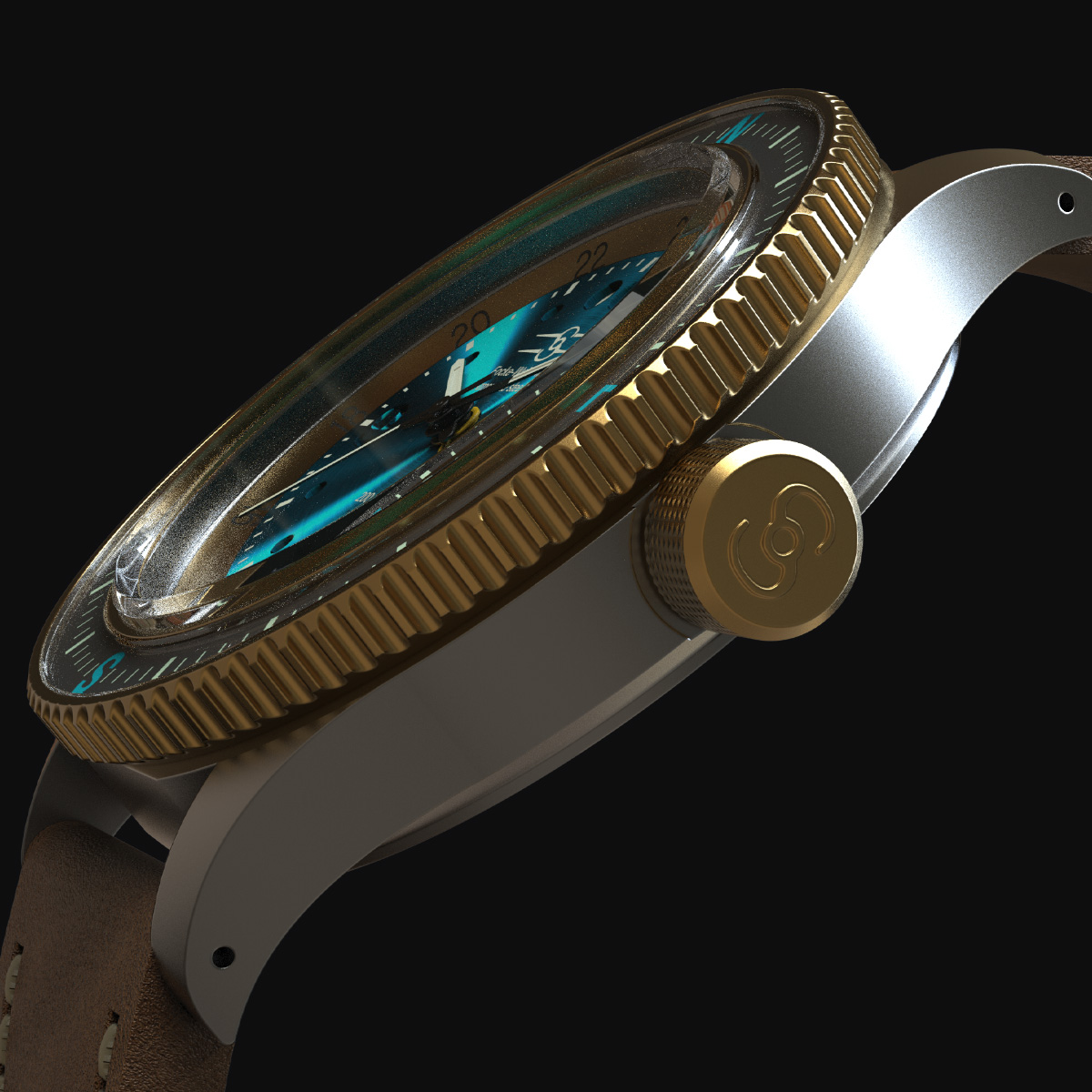

The case of the Sopwith Aero Marquis Focke-Wulf Fw 190 Baltic Winter Limited Edition was crafted from the cockpit armor of an original Fw 190 Luftwaffe fighter that was processed, melted and poured at Sopwith‘s foundry in Houston. The steel used for this watch case was rescued from the unsalvageable seat armor plate that protected the pilot’s head from a rear attack.

The Baltic Winter Limited Edition of the Sopwith Aero Marquis recaptures the coastal palette of cool, icy landscape tones so familiar to the Luftwaffe pilots of long ago. The dial and bezel colors meticulously recreate the hue of the deep blue ice of the Baltic Sea and the charcoal rocks that line its coast.

The hour and minute hands, bleached in snow white, are modeled after the indicator needles on the cockpit instrumentation of an original Fw 190. The lumed twin dots unique to Sopwith timepieces are visible at 12 o’clock.

The numerals on the bronze 24 hour chapter ring resemble the font used on the Focke-Wulf’s original altimeter and speed indicator. The German colors on the tri-bar at six o’clock pay homage to the Teutonic origins of the Focke-Wulf design.

Read

The SPECS

Case

Materials

Focke-Wulf Fw 190 hardened

steel cockpit armor plating

Caseback, 316L stainless steel, signed, engraved

Dimension

Ø 41.00 mm

Water Resistance

Water-resistant to 200 meters

Lug distance

21mm

Lug-to-lug

49 mm

Hardness

Titanium carbide coating 1500 HV

Enhanced historic steel 168.2 HV

manufacturing

Steel processed, melted, poured, cast, laboratory analysis, enhanced to 5360 grade steel at Sopwith Foundry, Houston USA

Finish

Bead blasted finish

Titanium carbide physical vapor deposition coating

Magnetic field resistance

20,000 Gauss

Dial & Hands

Dial

3 piece

Double stainless steel stacked

Oblique 25-degree bronze 24 hour chapter ring

Hands

Diamond cut steel

Bezel

Bronze

120-position

Unidirectional rotating

Azimuth +/-3 degrees

Luminous sapphire insert

Movement & Functions

Movement Type

Automatic, bidirectional rotor

Mecaline Specialities Calibre 2893-A2 Élaboré,

ETA SA Manufacture Horlogère Suisse, Grenchen, Switzerland

Power reserve, 42 hours

Frequency, 28,800 bph

21 jewels

Functions

Hours, minutes, seconds, GMT, azimuth

LUME

Swiss multi-layered, Swiss X1 grade Light Old Radium GL

Anti-shock system

Jeweled Incabloc SA Novodiac, Durnico steel/brass

La Chaux-de-Fonds, Switzerland

CROWN

Signed, extruded diamond grip bronze, 3.50 x 7.00 mm

Strap

Material

Stitched, hand-cut Horween leather

Color

Brown

Buckle

Tang buckle with Sopwith Logo emboss

Sopwith Aero Marquis

Focke-Wulf Fw 190 Series

Baltic Winter Limited Edition

Written and researched for Sopwith Watch Company by Barrett Tillman, award-winning author of “The Dauntless Dive-Bomber of World War II,” “When the Shooting Stopped: August 1945,” and more than 40 other books on World War II and the VietNam conflict

Through much of the war, the Luftwaffe’s Baltic command was Luftflotte (Air Fleet) One, headquartered in Latvia while conducting operations against the Soviets in Estonia, Lithuania, and Finland. The aviation component supported Army Group North, focused on the Leningrad front.

Chief among Luftwaffe fighter units in the Baltic was Jagdgeschwader 54 (JG 54), publicized as the “Green Hearts” for the wing’s emblem. Formed in Thuringia in 1939, the unit adopted the region’s motif as “the green heart of Germany.”

Jagdgeschwader 54 was a first to last combatant, flying against Poland, France, and Britain until transferred east in 1941. The wing only had five Kommodores throughout the war, notably Oberst (Colonel) Hannes Trautloft whose combat career began in Spain, and Oberstleutnant (Lieutenant Colonel) Hubertus von Bonin, killed in his Focke-Wulf 190 in December 1943. His successor, Oberstleutnant Anton Marder, fell ill ten months later.

At the outset of Germany’s invasion of Russia – Operation Barbarossa in June 1941 – the Luftwaffe counted nearly 4,400 aircraft of which 2,600 were deployed in the East. Thus, the Germans were outnumbered more than three to one by the Red Air Force. But the qualitative difference proved decisive in the early phase as the Luftwaffe gained air superiority for the first several months.

The Green Hearts scored heavily against the technologically inferior and less experienced Red Air Force. But then came Russia’s historic ally, “General Winter.” Flying and operating in that environment challenged the Germans over the next three winters. With Russian resilience, the Eastern Front settled into a grinding, four-year war of attrition.

Twenty-one Experten with more than 100 victories flew in whole or in part with JG 54. They faced Soviet fighter aircraft typically mounting both cannon and machine guns, as did Germany and Japan. The usual weapons, as in the much-produced Yakovlev series, were a nose-mounted cannon with two rifle-caliber machine guns. The 20mm ShVAK cannon’s standard projectile was claimed to defeat 10 to 15mm (0.39 to 0.60 inches) of homogeneous armor at close ranges.

Twin 7.62mm ShKAS machine guns generally augmented the cannon. Armor-piercing rounds were rated to penetrate 11mm (0.43 inches) of armor at 400 meters.

Russian and German home front efforts were felt at the sharp end of combat. In 1942 Russian factories delivered 25,000 aircraft, peaking at 40,000 two years later. However, U.S. and British lend-lease deliveries increased the disparity over Germany, which produced about 15,000 in 1942. Overall, Allied lend-lease deliveries totaled about 18,000 aircraft to the Soviet Union.

While producing prodigious numbers of planes, Russia improved aircrew selection and training. Gradually the Red Air Force’s deficits were reduced, brought to parity, and eventually reversed.

The Luftwaffe typically flew in an environment of numerical inferiority in the East, with an average of about 1,100 aircraft available. At the end of 1943 the command deployed as few as 425 fighters, presumably with many awaiting repair or spare parts. Attrition was constant. During 1943, Luftwaffe fighter losses in the East ran more than 300 per month. Meanwhile, as priorities evolved, single-engine fighter production rose from 200 in the first half of 1941 to nearly 800 in the first half of 1943.

The most active pilots found combat on 60 percent of their sorties. But conversely, many were shot down or crash landed repeatedly. Some joked that they bailed out enough times to qualify as paratroopers, and several jumped more than the requisite six times.

JG 5’s luminaries included Oberleutnant Otto Kittel (267 total, all with the wing); Major Walter Nowotny (258, all but two with the wing); Oberstleutnant (Lieutenant Colonel) Hans Philipp (206, 196 with the wing); and Major Erich Rudorffer (222, 69 with the wing). Most began combat in the Bf 109 but the Geschwader began transition to Focke-Wulf 190s in February 1943 when the Green Hearts claimed their 4,000th victory.

As one example, Hans Phillipp was a six-year veteran pilot with a stellar career. He became Germany’s fourth “century ace” in March 1942 and the second to reach 200 victories, in September of that year.

In April 1943 Philipp was transferred to the West, commanding Jagdgeschwader 1. It was a drastic change from Russia similar to other Ostfront veterans. That October Phillip wrote “Hannes” Trautloft, his former Kommodore, “Against 20 Russians trying to shoot you down, or even 20 Spitfires, it can be exciting, even fun. But to curve in towards 40 Fortresses and all your past sins flash before your eyes. And when you yourself have reached this state of mind, it becomes that much more difficult to have to drive every pilot of the Geschwader, right down to the youngest and lowliest NCO, to do the same.”

Days later Phillip was killed fighting Eighth Air Force P-47s, age 26.

Meanwhile, JG 54 continued its Ostfront campaign. From Barbarossa onward, wing headquarters moved twenty times, finally settling at Ciava, Latvia, during the last four months with FW-190A models augmented by the powerful “Dora” with a 1,700-horsepower Jumo 213 in-line engine.

At war’s end the Green Hearts claimed 9,600 victories, exceeded only by JG 52 with 10,000.

Contrarily, throughout the war the wing lost 733 pilots killed or missing plus 570 non flying personnel. Among the 1,800 aircraft missing or written off, about 750 (41 percent) were Focke-Wulfs, indicating the 190’s superior survivability over the Bf 109.

The Baltic Winter Limited Edition of the Sopwith Aero Marquis rescues unsalvageable armor plates from an original Fw 190 and preserves them for posterity in the form of a world-class timepiece.

Watch Case Warranty – Forever

Sopwith watch cases are guaranteed forever against manufacturing and workmanship defects, cracking, breaking, lug failure or structural damage to the steel as determined by Sopwith Watch Company. Case warranty does not include cosmetic damage and scratching from normal use.To submit a claim, send the complete watch to Sopwith Watch Company with a brief description of the damage. If a replacement is issued, it will be provided free of charge including re-assembly of the watch.

Due to the scarcity of historic steel, Sopwith may at its discretion substitute the case with one made from the steel of a different airplane/automobile/vehicle or replace the watch case with another model.

All Other Parts – 1 Year

Sopwith‘s 1-year warranty covers manufacturing defects excluding damage resulting from normal wear and tear, misuses or accidental impact (including but not limited to scratching or wearing of PVD coatings, scratches, chipping of crystal), unauthorized repair, opening watch case back, adjustment to movement or any other modification work done outside our authorized service center, damage done to bracelets, straps or accessories, water infiltration or damage in watch due to failure to secure screw-down crown or exposure of watch to depths exceeding rated water-resistance.

Aero Marquis Watch Case Manufacturing

Sopwith is proud to manufacture the finest – and rarest – watch cases in the world, guaranteed forever. Our proprietary steel enhancement process creates a watch housing that meets or exceeds industry standards while preserving the original historic metals.Steel manufactured under wartime conditions in the early 20th century was of poor quality, prone to rust, relatively soft and unsuitable for continuous contact with human skin. It was built to endure a few months of combat service before being destroyed or scrapped.

Once historic steel is rescued from destruction by Sopwith Watch Company, our staff metallurgists disassemble, wash and silicon blast each piece at the Sopwith Foundry. The individual components are then laboratory tested to determine their composition via a time-consuming and labor intensive process. The cylinders of a 1918 Gnome aviation engine – for instance – contain seven distinct types of steel, each of which must be individually analyzed. The laboratory analysis of every piece is then compared to the composition of Aerospace Material Specification 5360 grade stainless steel.

Each lot of historic steel is melted in-house at the Sopwith Foundry in Houston by Sopwith staff members. The steel is then enhanced with the necessary elements to raise the final metal to AMS 5360 grade, or – in the case of very old steel – as precisely as possible to AMS 5360.

In order to achieve AMS 5360 status, Sopwith must adhere to standards established by the Society of Automotive Engineers to create a steel that is suitable for use in specialized applications. These standards place exact limits on the elemental composition of the steel, minimum tensile and yield strengths, and solution heat-treated finishing.

Anti-magnetic and upgraded to AMS 5360 standards, the historic steel is cast into watch housings at the Sopwith Foundry. Each case is then polished and coated with a protective film of titanium carbide. The physical vapor deposition method was chosen for it’s lower application temperatures which preserve the precise elemental content of the steel.

The Sopwith Aero Marquis watch case is made of authentic historic steel, yet meets or exceeds industry standards for corrosion resistance, strength and durability. All Sopwith watch cases are guaranteed forever.

Related products

-

Limited to 53 watches.

Focke-Wulf Fw 190

Tunisian Desert$5,700.00 View cartFocke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case -

Limited to 55 watches.

Focke-Wulf Fw 190

Arctic Sea$4,900.00 View cartFocke-Wulf Fw 190

Case made from:

Cockpit Armor Plating

41 mm case -

Limited to 30 watches.

Thomas-Morse Scout

Limited Edition$10,500.00 View cartThomas-Morse S4C Scout

Case made from:

Le Rhone 9C steel pistons

41 mm case